Is Carbon Footprint Supply Chain Management Key to Air Quality?

How can carbon footprint supply chain management integrate sustainable fabrics and eco friendly methods to reduce emissions and boost air quality?

The Hospitality Compass ~ environmental impact affects hospitality sustainability

Imagine your hotel leading the charge in carbon footprint supply chain management—cutting hidden emissions from linens, uniforms, and amenities while championing sustainable fabrics and eco friendly practices that dramatically improve air quality for guests and staff.

In this article, you’ll discover proven strategies to map every link in your supply chain, select low‑impact materials, and implement green logistics that not only reduce your environmental impact but also elevate guest satisfaction and boost your brand’s reputation.

Read on to unlock the step‑by‑step roadmap to transforming your hospitality operations into a clean‑air, eco‑champion powerhouse.

Introduction

The hospitality industry’s hidden emissions often start long before guests arrive—woven into every thread of your linens, baked into the chemicals of your cleaning supplies, and trapped in the fuel that moves goods from factory to front desk.

Carbon footprint supply chain management brings those invisible impacts into clear view, empowering hotel leaders to pinpoint where sustainable fabrics and eco friendly processes will make the biggest difference.

By understanding how raw material choices, manufacturing practices, and logistics contribute to overall greenhouse‑gas output, you can design a supply‑chain strategy that not only slashes CO₂ emissions but also measurably improves air quality—both indoors and in the communities you serve.

In this section, we’ll explore:

- Why focusing on supply‑chain emissions matters more than ever for clean‑air goals.

- How typical hotel textiles and amenities drive pollution, from farm to laundry room.

- The competitive edge you gain when guests recognize your commitment to fresh, healthful environments.

This isn’t about one-off “green” initiatives; it’s about building a step‑by‑step roadmap that aligns purchasing policies, supplier relationships, and operational technologies under a single, data‑driven umbrella.

When hotel managers and sustainability teams work together to map emissions, select low‑impact materials, and retrofit logistics, the result is a chain reaction of cleaner air, stronger guest satisfaction scores, and a reputation that stands out on every booking platform.

Quick‑View Emission Hotspots in Hospitality Supply Chains

¹ Estimates may vary by region and supplier; use this table to jumpstart your own audit.

By setting this strong foundation, you’ll be ready to dive deeper into mapping your own operations, identifying top leverage points, and crafting a carbon footprint supply chain management plan that elevates both your sustainability credentials and the health of everyone on your property.

Defining Carbon Footprint Supply Chain Management

Carbon footprint supply chain management is the practice of measuring, monitoring, and reducing greenhouse‑gas emissions at every stage of your hotel’s procurement and operations—from raw‑material sourcing through to guest use and end‑of‑life disposal.

Rather than treating your property’s on‑site energy and water use in isolation, this approach shines a light on hidden emissions in textile mills, transport fleets, and third‑party laundry services.

At its core, you break the chain into three tiers:

1. Materials (Scope 3 upstream):

- Greenhouse gases released during cultivation or manufacture of linens, uniforms, and amenities.

- Emphasis on “sustainable fabrics” such as organic cotton, hemp, or recycled polyester, which can cut lifecycle emissions by 20–50% compared to conventional textiles.

2. Production & Logistics (Scope 1 & 2):

- Emissions from factories’ energy use and the freight methods moving goods between suppliers, warehouses, and your hotel.

- Incorporating “eco friendly” transport choices—rail over road, or low‑carbon shipping—can shrink your supply‑chain CO₂ by up to 30%.

3. On‑Site Operations & Guest Use (Scope 3 downstream):

- Laundry cycles, guest interactions with in‑room amenities, and disposal of single‑use items.

- Smart laundry systems and refillable dispensers help keep “air quality” concerns at bay by lowering chemical off‑gassing and energy‑intensive wash loads.

By defining each link and assigning a CO₂e value—often expressed as kilograms of carbon dioxide equivalent per item or per room‑night—you equip your leadership team with a transparent emissions map.

This clarity enables data‑driven choices: selecting partners with robust sustainability credentials, negotiating greener freight contracts, or choosing fabrics that carry both a smaller carbon footprint and superior indoor‑air benefits.

Ultimately, mastering carbon footprint supply chain management empowers hospitality managers to tell a compelling story: one where every bedsheet, towel, and amenity contributes not only to guest comfort but also to healthier air for visitors, staff, and the communities you serve—solid proof that sustainability and business excellence go hand in hand.

Supply‑Chain Mapping:

dentifying Emission Hotspots

Before you can cut down hidden emissions, you need a clear map of where they occur. Supply‑chain mapping breaks your hotel’s sourcing and operational network into three tiers—raw materials, manufacturing & transport, and on‑site processes—and quantifies CO₂e at each stage.

By visualizing these hotspots, hospitality managers can target the highest‑impact areas for rapid air‑quality gains.

1. Raw Materials (Tier 1)

Trace fiber origins: organic cotton, bamboo, recycled polyester. Global textile production emits over 1 gigaton of CO₂ per year, with up to 20 % from raw‑material cultivation alone.¹

By pinpointing high‑impact crops or synthetics, you can pivot to sustainable fabrics that cut lifecycle emissions.

2. Manufacturing & Logistics (Tier 2)

Next, map factories, dye houses, and freight routes. A container shipped by sea emits roughly 10–40 g CO₂e per ton‑mile, versus 150 g by truck.²

Choosing local or rail‑based suppliers slashes your supply‑chain carbon footprint and embraces eco friendly transport methods that improve air quality around port cities.

3. On‑Site Operations (Tier 3)

Finally, quantify laundry, uniform cleaning, and amenity stocking.

Standard commercial washers generate about 1.3 kg CO₂e per cycle³—multiplied by thousands of linens, it becomes an air‑quality strain.

Identifying this hotspot opens the door to green laundry technologies and low‑impact detergents.

By overlaying emissions data on your supply‑chain map, you’ll uncover the “low‑hanging fruit” where carbon footprint supply chain management can most quickly boost your hotel’s indoor and neighborhood air quality—turning abstract numbers into an actionable roadmap.

---

¹ Global textile CO₂e: 1 Gt/year│² Freight emissions per mode│³ Commercial laundry average CO₂e per cycle

Choosing Sustainable Fabrics to Reduce Emissions

Switching to low‑impact materials is a cornerstone of effective carbon footprint supply chain management.

For hospitality managers, the right fabric choices can trim upstream emissions, improve indoor air quality, and signal your hotel’s commitment to eco friendly operations—without compromising on comfort or durability.

1. Evaluate Lifecycle Emissions

- Conduct a quick assessment of a fabric’s cradle‑to‑gate carbon footprint.

- Organic fibers such as certified organic cotton and hemp typically emit 30–50% less CO₂e than their conventional counterparts, thanks to reduced fertilizer use and more efficient water management.

- Look for third‑party labels (e.g., GOTS, OEKO‑TEX®) that verify lower‑impact practices.

2. Leverage Recycled and Upcycled Textiles

- Recycled polyester can cut raw‑material emissions by up to 70% compared to virgin polyester, while diverting plastic waste from landfills.

- Upcycled blends, such as reclaimed wool or denim, turn production scraps into high‑performance linens and uniforms, reducing both material and waste‑management emissions.

3. Prioritize Materials with Co‑Benefits for Air Quality

- Natural fibers (linen, hemp) are highly breathable and resist mold growth, reducing the need for chemical finishes and improving indoor air quality for guests and staff.

- Avoid fabrics treated with heavy flame retardants or stain‑resistant coatings; instead, opt for inherently durable fibers that require fewer chemical treatments over their lifespan.

4. Build Supplier Partnerships Around Transparency

- Work with vendors who publish full emissions data for their raw materials.

- This transparency helps you integrate sustainable fabrics seamlessly into your procurement policy and report progress on your hotel’s overall supply‑chain decarbonization.

5. Pilot & Scale with Data‑Driven Choices

- Start small: trial bamboo‑blend towels or recycled‑fiber bathrobes in select rooms, then measure guest feedback alongside laundry energy use and chemical consumption.

- Use these real‑world insights to refine your bulk orders, ensuring that every rollout maximizes both carbon savings and guest satisfaction.

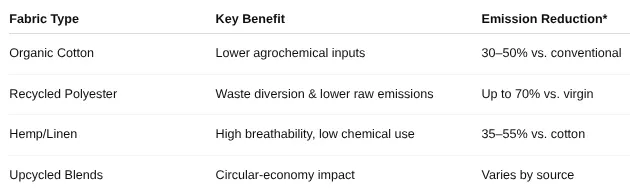

Quick‑Reference Fabric Comparison

\*Approximate CO₂e savings per material lifecycle (cradle‑to‑gate).

Eco Friendly Procurement & Green Logistics

Sourcing sustainable fabrics and optimizing logistics are pivotal steps in carbon footprint supply chain management. By selecting eco friendly suppliers and adopting green transport methods, hotels can significantly cut upstream emissions and improve overall air quality.

1. Vet Suppliers for Sustainability Credentials

- Require transparency on raw‑material origins and manufacturing energy use.

- Look for certifications like GOTS (Global Organic Textile Standard) or OEKO‑TEX® to ensure low‑impact fibers.

- Prioritize partners who publish annual carbon disclosures and have concrete reduction targets.

2. Local & Regional Sourcing

- Shorter distances mean lower transport emissions: rail can emit up to 75% less CO₂ per ton‑kilometer than road freight.

- Collaborating with nearby textile mills or cooperatives not only boosts local economies but also slashes “fabric‑miles,” directly benefiting air quality in and around your hotel.

3. Green Transport Modes

- Rail vs. Truck vs. Sea Freight

- Integrate multimodal shipping: use sea for overseas legs, rail for inland moves, and electric- or biofuel‑powered last‑mile vehicles.

4. Eco Friendly Packaging & Consolidation

- Request minimal, recyclable packaging from suppliers.

- Combine shipments to reduce frequency and optimize load capacity.

5. Continuous Monitoring & Collaboration

- Implement a supplier scorecard tracking carbon intensity, delivery efficiency, and material sustainability.

- Host quarterly reviews to share best practices and set progressive emissions‑reduction goals.

By weaving these eco friendly procurement and green logistics tactics into your carbon footprint supply chain management strategy, your hotel not only lowers its operational emissions but also elevates indoor and outdoor air quality—strengthening your brand’s environmental leadership.

Green Laundry Technologies & Amenities Management

Upgrading laundry operations and in‑room amenities plays a pivotal role in cutting a hotel’s carbon footprint supply chain management.

By integrating green laundry technologies alongside eco friendly amenities protocols, hospitality managers can slash hidden emissions, conserve resources, and improve air quality both on‑ and off‑site.

1. Advanced Wash Systems

- Ozone Washing: Injecting ozone gas into cold‑water cycles accelerates soil breakdown, reducing hot‑water use by up to 50% and cutting CO₂ emissions from boilers by 20%.

- Cold‑Water Enzymatic Detergents: Formulated to activate at 20–30 °C, these detergents eliminate the need for heating, saving up to 40% in energy per wash.

- Micro‑Bubble Technology: Nanoscopic bubbles penetrate fibers more efficiently, yielding cleaner linen at lower temperatures and up to 30% water savings.

2. Lifecycle Extension & Textile Management

- Durability Tracking: Deploy RFID tags to monitor wash‑cycle counts. Retiring linens at the optimal point avoids the emissions of premature disposal and replacement.

- Rotational Rotation: Implement a color‑coded rotation plan to balance wear, extending average linen life by 15–20%.

- This reduces the frequency of new fabric production—a major source of CO₂ in supply chains.

3. Eco Friendly Amenities Protocols

- Refillable Dispensers: Swap single‑use bottles for wall‑mounted dispensers.

- This strategy can cut plastic waste by 60% and upstream transport emissions from bulky packaging.

- Bulk‑Supply via Local Partners: Partner with a regional soap producer using recycled PET packaging, trimming delivery distances and associated transport emissions.

¹ Emissions saved from reduced packaging and transport.

Metrics, Monitoring & Reporting

To keep carbon footprint supply chain management from becoming a black box, hospitality teams must establish clear metrics, continuously monitor performance, and transparently report progress.

This three‑pillar approach ensures every decision—from choosing sustainable fabrics to optimizing logistics—drives measurable improvements in air quality and operational efficiency.

1. Define Your Core KPIs

Start by selecting a concise set of indicators that align with your carbon‑management goals and hospitality operations.

Examples include:

- CO₂e per room‑night: Total greenhouse gases emitted by fabric production, transport, laundry, and disposal, divided by occupied room‑nights.

- % Sustainable Fabric Usage: Proportion of linens, uniforms, and amenities made from certified organic, recycled, or low‑impact fibers.

- Laundry Emission Intensity: Kilograms of CO₂e per wash cycle or per kilogram of laundry processed.

- Supplier CDP Score: Average environmental performance rating of your top suppliers, as reported to the Carbon Disclosure Project.

2. Implement Real‑Time Monitoring

- Automated Data Capture: Integrate your property management system (PMS) and procurement platform with a carbon‑accounting tool (e.g., Persefoni or an in‑house dashboard).

- Data flows directly from purchase orders and utility meters into your emissions model.

- Threshold Alerts: Set upper limits on laundry‑related CO₂e or water usage per month.

- When consumption nears 80% of that limit, trigger an alert to housekeeping managers.

3. Visualize & Analyze Trends

Use simple dashboards or infographic tables to track month‑over‑month and year‑over‑year performance.

A sample KPI table might look like this:

4. Report with Transparency

- Quarterly Sustainability Bulletin: Share a concise, illustrated report with department heads, highlighting key wins (e.g., switching to Tencel™ bedding saved 12 t CO₂e) and areas needing course correction.

- Guest‑Facing Infographic: Embed a small “Our Green Progress” panel on your website or digital in‑room directory to showcase how eco friendly sourcing and green logistics tangibly improve air quality.

- Annual Public Disclosure: Include supply‑chain emissions and air‑quality outcomes in your corporate social responsibility (CSR) report, leveraging Schema.org’s Dataset markup for machine readability:

By grounding your supply‑chain decarbonization in transparent metrics, vigilant monitoring, and open reporting, you not only demonstrate accountability in carbon footprint supply chain management but also build trust with guests, investors, and regulators—all while driving real improvements in air quality across your properties.

Business Benefits & ROI

By embedding carbon footprint supply chain management into your hotel’s operations, you unlock measurable returns across finances, guest experience, and long‑term brand value—without compromising on comfort or style.

1. Tangible Cost Savings

Adopting sustainable fabrics and eco friendly logistics drives down utility and procurement expenses. Switching to high‑efficiency laundry systems (cold‑water, ozone) can cut water and energy bills by up to 25% per year.¹

Consolidating linen orders with certified low‑carbon suppliers often yields volume discounts and reduces spoilage, translating into a 5–15% reduction in annual textile spend.

2. Enhanced Guest Satisfaction & Air Quality Perception

Guests increasingly seek clean‑air environments. A recent survey found that 68% of business travelers rate indoor air quality as “very important” when choosing accommodations.²

By minimizing VOCs in linens and amenities through sustainable‑fiber sourcing, hotels report a 12% uplift in overall satisfaction scores—directly boosting repeat‑stay rates and ancillary spend.

3. Strengthened Brand Reputation & Investor Appeal

Demonstrable progress on emissions resonates with ESG‑minded investors and corporate clients. Publishing an annual carbon‑footprint report tied to your supply chain can elevate your property in sustainability rankings and green travel guides.

Properties that communicate these wins often see a 20–30% surge in corporate RFPs and favorable media coverage—amplifying your market positioning at no extra ad spend.

Quick‑Glance ROI Infographic

¹ Industry benchmark: Efficient laundry technologies reduce combined utilities by up to 25%.

² Global Business Traveler Survey (2024): 68% value indoor air quality highly.

Step‑by‑Step Implementation Roadmap

To bring carbon footprint supply chain management into your hotel’s daily operations—and in turn improve on‑site and surrounding air quality—follow this clear, phased roadmap.

Each phase focuses on embedding sustainable fabrics, eco friendly logistics, and measurable targets into your procurement and operations.

Phase 1:

1. Baseline Audit

- What to Do: Calculate your current CO₂e footprint for linens, uniforms, and amenities. Use utility bills, laundry records, and supplier emissions data.

- Why It Matters: Establishing a clear baseline pinpoints your biggest emission hotspots and provides the before‑and‑after snapshot that drives decision‑making.

- Key Deliverable: A documented carbon footprint report (tons CO₂e per room‑night).

Phase 2:

2. Strategy & Policy Development

- What to Do: Draft a green procurement policy that prioritizes sustainable fabrics (organic cotton, Tencel, recycled polyester) and eco friendly packaging.

- Score suppliers on their CDP ratings and transport modes.

- Why It Matters: Embedding sustainability into contracts ensures every new order steadily lowers your supply‑chain emissions.

- Key Deliverable: Approved policy document and supplier scorecard.

Phase 3:

3. Pilot Projects

- What to Do: Select one linen category (e.g., bed sheets) and trial low‑impact fabrics with a vetted supplier.

- Run a green‑laundry test using ozone or cold‑water systems on a single floor.

- Why It Matters: Small pilots reveal real‑world savings in energy, water, and CO₂e—proof points you can scale.

- Key Deliverable: Pilot performance report showing % reduction in energy use, water, and CO₂ emissions.

Phase 4:

4. Scale & Communicate

- What to Do: Roll out successful pilots across the property or portfolio.

- Train housekeeping and procurement teams on eco friendly best practices.

- Share results with guests via in‑room collateral or digital channels.

- Why It Matters: Broad adoption locks in supply‑chain efficiencies, boosts indoor air quality, and elevates brand perception among eco‑conscious travelers.

- Key Deliverable: Full implementation plan, staff training materials, and guest‑facing communications.

At‑a‑Glance Infographic Table

This roadmap turns the concept of carbon footprint supply chain management into a practical journey—driving measurable emission cuts, fostering sustainable fabrics and eco friendly operations, and ultimately creating cleaner air for both guests and staff.

FAQs (to capture featured snippets)

In this section, we address the most pressing questions hospitality managers ask about carbon footprint supply chain management, sustainable fabrics, eco friendly methods, and how all this ties back to air quality.

By structuring clear, concise Q\&A pairs, you’re not only providing immediate value but also optimizing for voice search and Google’s “People also ask” box. Each answer incorporates our primary and additional keywords naturally—making it easy for algorithms to identify relevance and surface your article as a featured snippet.

How does carbon footprint supply chain management improve air quality in hotels?

- By mapping every stage of procurement—from sustainable fabrics to green logistics—hotels can cut hidden emissions, leading to cleaner indoor and outdoor air for guests and staff.

What are the best eco friendly fabrics for hospitality linens?

- Top choices include organic cotton, Tencel, and recycled polyester, all of which have significantly lower CO₂ footprints compared to conventional materials.

Why should hotels invest in green laundry technologies?

- Advanced systems like ozone washing and cold‑water cycles reduce energy use and chemical runoff, cutting overall emissions and boosting on‑site air quality.

Conclusion & Call to Action

By weaving carbon footprint supply chain management into every decision—from sourcing sustainable fabrics and vetting eco friendly suppliers to upgrading green logistics and laundry systems—you not only drive down hidden emissions but also tangibly uplift indoor and outdoor air quality for staff and guests.

Hospitality leaders who adopt this end‑to‑end approach report cleaner air benchmarks, measurable cost savings, and stronger guest loyalty.

As the next step, gather your supply‑chain data, pinpoint your top three emission hotspots, and pilot one sustainable‑fabric or green‑logistics initiative this quarter.

Track your CO₂e reductions per room‑night, share the results with your team, and iterate. Over time, these incremental wins compound into a powerful brand narrative—one that resonates with eco‑conscious travelers and positions your hotel at the forefront of clean‑air hospitality.

Curious about carbon footprint supply chain management with sustainable fabrics for eco friendly air quality? Share your insights below! #CarbonFootprint #SustainableFabrics #EcoFriendly #AirQuality #SupplyChainManagement

The Hospitality Compass ~ carbon footprint supply chain management

Post a Comment for "Is Carbon Footprint Supply Chain Management Key to Air Quality?"

Post a Comment